Why suspension needs service

For serious mountain bikers, a well-maintained suspension system is the difference between ripping descents with confidence, or white-knuckling their way down in fear. Beyond basic adjustments, a periodic suspension service is crucial to ensure optimal performance and component longevity. This article dives into some of the technical aspects of suspension service, empowering bike mechanics with the knowledge to confidently speak to their customers about recommended services and adjustments to their suspension forks and shocks.

The Service Breakdown

A comprehensive suspension service typically involves a systematic approach:

1. Disassembly and Cleaning

We’re talking complete tear-down here. Air springs, damping cartridges, and lower legs all get separated. Each component receives a thorough cleaning using appropriate solvents and lubes to remove grime, debris, and old oil.

2. Inspection and Wear Assessment

A meticulous inspection of all components is crucial. This means checking for wear on bushings, seals, stanchions, and damper internals. Worn parts can lead to poor performance and potential damage down the line, so replace them as needed.

3. Lower Leg Service (Forks only)

Here, we focus on replacing worn dust wipers and foam rings, ensuring proper bushing lubrication, and inspecting the stanchions for damage. Don’t forget – a scratched stanchion can compromise fork seal integrity.

4. Air Spring Service

This usually involves cleaning and relubricating air seals, checking for air leaks, and potentially servicing the air valve itself. Remember, some air springs have specific service procedures depending on the design. In rear shocks, the air canister also acts as the primary layer of defence against the outside elements. Regular servicing and replacing of these seals will prevent debris from entering the damper and ruining performance.

5. Damping Service

This is the heart of the service and requires the most expertise. Depending on the damper complexity and condition, it could be as simple as removing the old oil and replacing it with new oil, or can involve disassembling the cartridge, replacing worn seals and o-rings, and potentially even replacing specific damping components based on wear or desired performance characteristics.

Oil Weight And Volume

Oil type and viscosity play a critical role in damping performance. Always refer to the manufacturer’s recommendations based on rider weight, riding style, and terrain. Remember, the right oil level is essential. Too much oil creates a harsh and sluggish feel, while too little leads to inadequate damping and potential damage. Use manufacturer-specified tools or procedures for precise oil volume measurement.

Post-Service Adjustments

Proper setup and adjustments are vital for optimal performance after a service. This may involve setting sag (static rider weight on the suspension), adjusting air pressure, and fine-tuning compression and rebound damping based on the rider’s preferences and riding conditions.

Pro-Level Considerations

For those who crave deeper knowledge and performance:

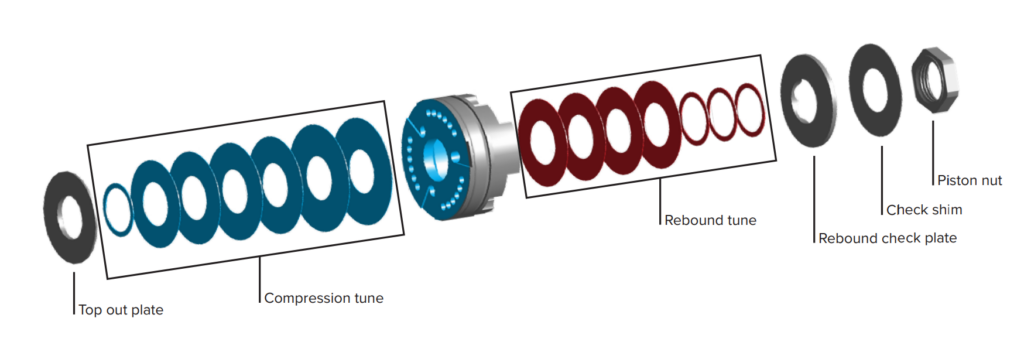

Shim Stacks and Damping Control

Many high-performance dampers utilize shim stacks to regulate oil flow and create specific damping characteristics. Understanding shim configurations and their impact on damping behavior allows for advanced tuning for specific riding styles.

Custom Tuning Options

Some manufacturers or aftermarket companies offer customized shim stacks or even complete damper upgrades to personalize damping characteristics beyond factory settings.

Nitrogen Inflation

Nitrogen is sometimes used in air shocks instead of regular air. It offers benefits like reduced pressure fluctuation with temperature changes and potentially improved damping consistency. However, it requires a specific inflation tool and may not be readily available in all shops.

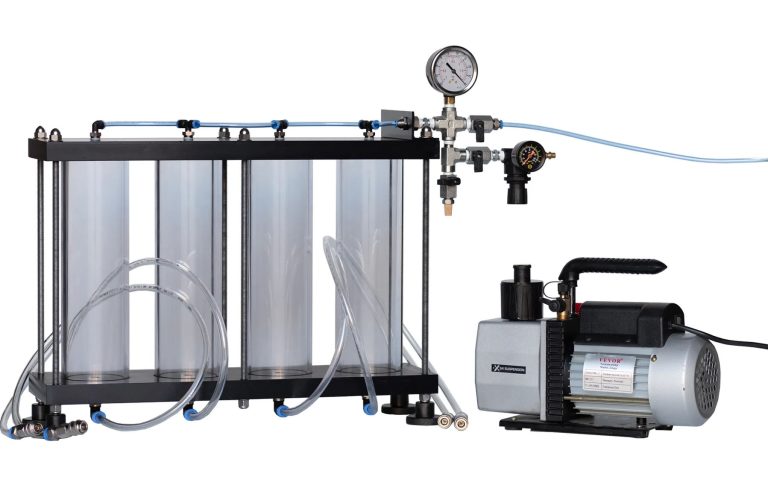

Vacuum Bleeding

Vacuum bleeding a damper is a technique using a specialized tool, a vacuum pump, to remove air from the internal chambers of a suspension damper, leading to improved performance and smoother operation. The vacuum creates a stronger force than manual methods, ensuring more thorough removal of air bubbles trapped within the damper. These air bubbles can cause erratic damping performance and are responsible for most of the “squelching” noise often heard from failed or ill-maintained dampers.

The Takeaway

A well-executed suspension service is an investment that pays off in rider satisfaction. By understanding the components, procedures, and technical details involved, you can ensure that your customers experience smooth, controlled, and confidence-inspiring rides. Remember to consult manufacturer manuals and recommendations, and invest in the appropriate tools and knowledge before attempting advanced service procedures. After all, happy riders lead to repeat business!