Complete Guide to Bicycle Bearings

Sizes, Types, Materials, and Ratings Explained

Bearings are small but crucial components of a modern bicycle. In fact, for obvious reasons, a bike wouldn’t be a bike without them! From the speed of a smooth-rolling hub, to the longevity of a sturdy bottom bracket and the precision steering of a well maintained headset, each bearing plays a role in managing friction and supporting critical load-bearing points on the bike. Yet, with so many variations in bearing size, type, material, and rating, even experienced riders and mechanics can find themselves wondering how to make the best choice for each application.

This guide delves into the nuances of bicycle bearings, breaking down the specifics of sizing systems, radial and angular contact types, and materials like steel versus ceramic. We’ll also cover what ABEC ratings really mean for bicycle use and help you navigate non-standard sizes. If you’re looking to refine your knowledge on bearing selection, installation, and maintenance, this article will give you the insights needed to make informed choices that enhance bike performance and longevity.

The Basics of Bicycle Bearings

What Are Bearings?

Bearings are essential components that reduce friction and allow smooth rotation in bicycle parts, such as hubs, headsets, bottom brackets, and pedals. They come in various designs to support different types of loads and applications.

Types of Bearings in Bicycles

- Loose Ball Bearings

Found mainly in older models or specific components like hubs, loose ball bearings, require cups and cones for installation but are easier to clean and re-lubricate. - Cartridge Bearings

Pre-assembled, sealed units that are easy to install and maintain. They’re prevalent in modern bicycles due to their durability and ease of replacement.

For the remainder of this discussion, we’ll be focusing specifically on cartridge bearings.

Radial, Roller, and Angular Contact Bearings

- Radial Bearings

Radial bearings are the most common type in bicycles, especially in hubs and suspension pivots. These bearings use rows of small, spherical balls positioned between an inner and outer race. Radial bearings are designed to support radial loads—loads that apply force perpendicular to the bearing’s axis. They’re ideal for high-speed rotation with minimal friction, making them suitable for applications where smooth, low-resistance rotation is crucial. However, radial bearings are less effective at handling axial loads, which are forces that act along the bearing’s axis, unless they are paired with seals or support from other components. - Roller Bearings

Roller bearings are a bit different from radial bearings in that they use cylindrical rollers instead of spherical balls. This design provides a larger contact area with the races, making roller bearings excellent for handling higher radial loads. Roller bearings are less common in bicycles due to their heavier and bulkier design, but they can occasionally be found in shock hardware, pedals or other bike components that need to bear heavier loads. Unlike radial bearings, roller bearings are not suitable for handling significant axial loads and aren’t optimized for the high-speed rotation often required in bicycles. - Angular Contact Bearings

Angular contact bearings are a specialized type of bearing designed to handle both radial and axial loads simultaneously. They have an offset angle that allows them to support loads that push or pull along the bearing’s axis, making them ideal for areas of the bike where lateral or twisting forces are at play—like in high-performance bottom brackets and many headset applications. Angular contact bearings provide more stability under multi-directional forces than standard radial bearings, though they often need to be installed in pairs or groups to balance the load direction. These bearings also need to be combined with a preloading system. Preloading stabilizes the bearings, ensuring consistent contact and preventing excess wear and damage over time.

Why Bearing Type Matters

Choosing the right type of bearing for each part of the bicycle is essential. Radial bearings are suited for high-speed components with low axial load requirements, like hubs, while angular contact bearings are better for areas experiencing mixed loads, in high-torque situations, like headsets and bottom brackets. Understanding the load conditions and selecting the appropriate bearing type ensures efficient, durable, and smooth operation across all components of the bike.

Decoding Bearing Size Designations

How Bearings Are Sized and Identified

Bearings are typically identified by a series of numbers and letters that specify their dimensions, type, and sealing options. This identification system allows mechanics to quickly understand the bearing’s specifications and intended application. Let’s break down a typical bearing code and its components.

Understanding Bearing Identification Codes

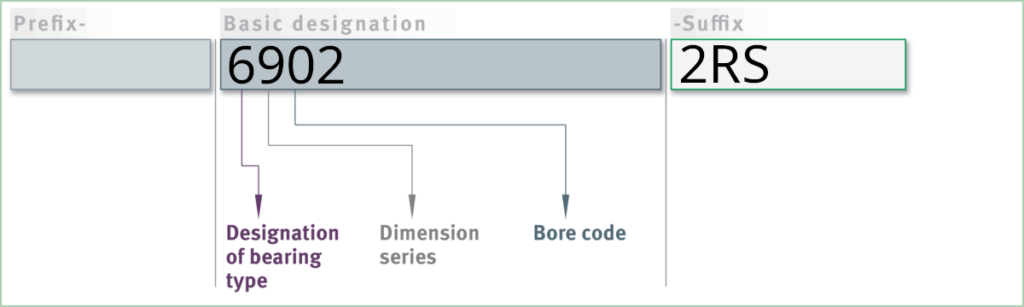

A bearing code might look something like “6902-2RS”, which includes numbers and letters that convey specific information about the bearing’s type, dimensions, and sealing. Here’s what each part of this code represents:

Basic Designations

- First digit or letter:

Indicates the bearing type and sometimes a basic variant. - Next two digits:

Represent the ISO dimension series. The first digit shows the width or height series, while the second identifies the diameter series. - Last two digits:

Specify the bore size code. Multiply this code by 5 to find the bearing bore diameter in millimeters

Exceptions and Special Cases

Some variations exist within this designation system:

- Omitted Digits:

Occasionally, the digit for bearing type or the first digit of the dimension series is omitted. - Small Standard Bore Sizes:

Bearings with bore diameters of 10, 12, 15, and 17 mm use unique codes:Code Inner diameter (ID) 00 10mm 01 12mm 02 15mm 03 17mm

- Omitted Digits:

- Very Small or Large Bore Sizes:

- For bore diameters below 10 mm or above 500 mm, the diameter is usually specified in millimeters without a size code. For example, “618/8” means an 8 mm bore, while “511/530” means a 530 mm bore.

- Some ISO 15 standard bearings with uncommon diameters (22, 28, or 32 mm) also follow this rule, like “62/22” for a 22 mm bore.

- For bore diameters below 10 mm or above 500 mm, the diameter is usually specified in millimeters without a size code. For example, “618/8” means an 8 mm bore, while “511/530” means a 530 mm bore.

- Uncoded Bore Diameters:

- Certain smaller bearings (e.g., deep groove, self-aligning, or angular contact bearings) use uncoded millimeter values without a slash, like “629” for a 9 mm bore.

- For bore diameters that don’t match standard dimensions, the actual diameter is listed in millimeters up to three decimal places, separated by a slash, such as “6804/29.5” (indicating a 29.5 mm bore).

- Certain smaller bearings (e.g., deep groove, self-aligning, or angular contact bearings) use uncoded millimeter values without a slash, like “629” for a 9 mm bore.

This designation system helps identify and categorize each bearing type, making it easier to select the right fit for specific bike components and applications. Understanding these designations will streamline the selection process and help you match the ideal bearing to your needs. Mechanics can use bearing charts or tables to quickly verify these dimensions if they know the series and bore size.

Other Identification Systems

Standard bearing sizing is essential for industrial efficiency, but a one-size-fits-all approach doesn’t work in every case. Some applications demand custom-sized bearings tailored to specific needs, especially in bicycles, where space constraints and unique loading conditions often require bearings outside typical sizing codes.

Manufacturers can create their own sizing systems to accommodate specialized needs, such as Enduro Bearings’ alphanumeric identification system. This custom system allows for non-standard bearing dimensions and features, making it possible to address specific demands in applications like high-performance bicycles. For instance, in Enduro’s system, codes like “MR 18307 LLB” indicate a metric radial bearing with specific measurements (18x30x7 mm) and LLB seals, while “DRF 152610 LLB” refers to a double-row, flanged radial bearing sized 15x26x10 mm with the same sealing. This level of customization supports performance and durability where standard sizes may not suffice.

Suffixes for Sealing and Shielding

Bearings are often available with various seals or shields that protect against contaminants or reduce friction. These suffixes appear at the end of the code and specify the type of protection:

- 2RS (Double Rubber Seal): Bearings with rubber seals on both sides are marked as 2RS. These seals offer excellent protection against water and dirt, making them ideal for bottom brackets and other exposed areas.

- ZZ (Double Metal Shield): Metal shields provide some protection from debris while allowing for lower friction. ZZ bearings are best for cleaner, high-speed environments like wheel hubs.

- RS (Single Rubber Seal): Some bearings have a seal on only one side, designated as RS. These are less common but can be useful when only one side is exposed to contaminants or when reduced friction is desired on one side.

Understanding ABEC Ratings for Bicycle Bearings

What is the ABEC Rating System?

The ABEC (Annular Bearing Engineers’ Committee) rating is a standard used to measure the precision and tolerance of ball bearings. This system primarily focuses on dimensional tolerances rather than load capacity, materials, or other quality factors. ABEC ratings range from 1 to 9, with higher numbers indicating greater precision.

ABEC Ratings and Bicycles: What to Know

Bearings with higher ABEC ratings, such as ABEC-7 or ABEC-9, are typically manufactured with tighter tolerances and greater precision, leading to smoother rotation and better efficiency at very high speeds. However, for bicycles, especially for mountain bikes and road bikes, higher ABEC ratings don’t always translate to noticeable performance gains. Bikes generally don’t reach speeds or loads where ultra-precise ABEC ratings become essential, so for many applications, an ABEC-3 or ABEC-5 bearing is more than sufficient.

Common ABEC Ratings in Bicycle Bearings

- ABEC-1: Basic precision and affordable, but less smooth compared to higher-rated bearings. Suitable for budget builds or areas with limited performance impact.

- ABEC-3: This rating is the most common in bicycle bearings, offering a good balance of precision, durability, and cost.

- ABEC-5: A higher precision bearing, often found in higher-end bikes or performance-focused builds. ABEC-5 bearings offer smooth rotation with minimal play, ideal for hubs or bottom brackets.

- ABEC-7 and ABEC-9: Generally considered overkill for most bicycles. While these bearings offer the highest precision, they are typically reserved for applications requiring ultra-high speeds and minimal friction—beyond what typical cycling demands.

Does ABEC Rating Matter for Bicycle Bearings?

- Bearing Materials and Sealing Matter More

While ABEC ratings can influence bearing smoothness, material quality and sealing (such as 2RS rubber seals) play a more critical role in durability for bicycles. Higher ABEC ratings don’t necessarily mean better wear resistance or strength under heavy loads; in fact, a well-sealed ABEC-3 bearing can outlast an ABEC-7 bearing when exposed to water, dirt, or rough terrain. - Cost vs. Performance

ABEC ratings can affect the price significantly. For most cycling applications, an ABEC-3 or ABEC-5 bearing will perform reliably without the high cost associated with ABEC-7 or ABEC-9 bearings, making them a more cost-effective choice. - When to Choose Higher ABEC Ratings

For specific high-performance applications, such as track racing or high-speed time trials, where friction reduction is crucial, ABEC-5 or even ABEC-7 might be worth considering. However, for everyday use, weather-resistant sealing and material strength are usually more impactful.

While ABEC ratings can provide some insight into bearing precision, it’s essential to consider the actual needs of your bike and riding conditions. Often, an ABEC-3 or ABEC-5 bearing with robust sealing and quality materials will outperform a high-rated bearing in real-world cycling conditions. By understanding ABEC ratings and their practical relevance, you’ll be able to make informed choices that balance cost, durability, and performance for each component on your bike.

Bearing Materials: Steel vs. Ceramic

Why Bearing Material Matters

The material used in a bearing affects its performance, longevity, cost, and resistance to environmental factors. In the bicycle world, bearings are commonly made from steel or ceramic, each offering unique benefits and drawbacks depending on the type of cycling and specific conditions. Let’s dive into the most popular bearing materials and when each is best used.

Steel Bearings

Steel bearings are the most commonly used bearings in bicycles due to their durability, affordability, and resilience.

- Materials and Types: Most steel bearings are made from high-grade stainless or chrome steel, chosen for their hardness and wear resistance. Stainless steel offers slightly better corrosion resistance, while chrome steel provides a slightly harder and more cost-effective option.

- Performance: Steel bearings deliver excellent durability and can handle significant loads, making them ideal for high-impact areas like bottom brackets and hubs. However, steel bearings tend to have more friction compared to ceramic options and may require regular cleaning and lubrication to maintain smooth performance, especially in wet or muddy conditions.

- Cost and Practicality: Steel bearings are affordable, easy to find, and relatively easy to maintain. For most riders, they offer a reliable and cost-effective solution, especially for everyday riding and mountain biking, where durability is more critical than weight or minimal friction.

Ceramic Bearings

Ceramic bearings, often found in high-end performance bikes, are made with ceramic balls instead of steel, offering certain advantages in terms of speed, smoothness, and weight.

- Materials and Types: Ceramic bearings typically use silicon nitride, a hard, smooth material resistant to corrosion. There are two main types of ceramic bearings:

- Full Ceramic: Made entirely from ceramic, including the balls and races. These are rare and generally not recommended for cycling due to their brittle nature under heavy loads.

- Hybrid Ceramic: The more popular choice for bikes, these bearings use ceramic balls with steel races, combining the benefits of both materials.

- Full Ceramic: Made entirely from ceramic, including the balls and races. These are rare and generally not recommended for cycling due to their brittle nature under heavy loads.

- Performance: Ceramic balls are lighter, smoother, and harder than steel, which reduces friction and can result in a small performance gain, especially at high speeds. They also don’t corrode, so they’re ideal for wet or corrosive environments. However, ceramic bearings are more brittle than steel, meaning they may not handle heavy or shock loads as well, which can be a factor in mountain biking or rugged terrain.

- Cost and Maintenance: Ceramic bearings tend to be significantly more expensive than steel bearings. For racers and competitive cyclists, the reduced friction and lighter weight might justify the cost, but for most recreational riders, the performance gain is minimal. Additionally, while ceramic balls are low-maintenance, hybrid ceramic bearings still require steel race maintenance, including periodic cleaning and lubrication.

Which Material to Choose?

- Steel Bearings: Ideal for most recreational, commuter, and mountain bike riders who prioritize durability and ease of maintenance.

- Hybrid Ceramic Bearings: Best for competitive cyclists, road racers, or anyone looking to gain marginal speed improvements with less friction, provided they don’t mind the additional cost.

Conclusion

Mastering the details of bicycle bearings can elevate your bike maintenance skills and enhance overall performance. From identifying the right bearing size and type—whether radial, roller, or angular contact—to selecting between steel or ceramic materials, each decision directly impacts your bike’s efficiency and durability. Whether you’re optimizing a road bike for speed, a mountain bike for rugged trails, or a commuter bike for reliability, understanding how to choose and install the right bearings is key. With this guide as your resource, you’re ready to tackle any bearing replacement or upgrade with confidence, ensuring smooth, reliable rides for miles to come.

Workshop optimization with VELODROP

Streamline your bike shop’s workflow with Velodrop—the software designed to simplify online booking, and workshop management.